Application

Industrial ion exchange and adsorbent resins

This section aims to summarize the typical column-wise processes in which Relite ion exchange and adsorbent resins are applied.

Primary water treatment

Based on the specific requirement, boiler and process water could be:- decalcified (softened) by interchange on Na form cation resins

- demineralised on cation – anion resins, for the maximum purity level achievement

Products purification

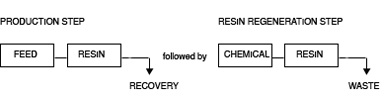

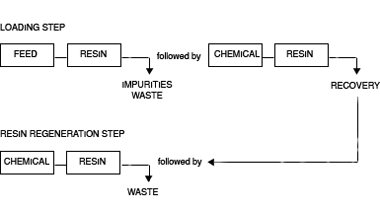

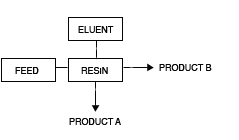

Different compounds can be recovered from aqueous solutions by ion exchange and /or adsorbent resins.Three possible ways are generally considered:

A) Impurities elimination

Examples:

- Sugar and sweeteners

- Organic acids

- Gelatine

- Boron removal

- Heavy metals removal

- Brine decalcification

- Brine desulphatation

- Chlorinated solvents removal

- Aromatic solvents removal

- Grape must

- Citrus juice debittering/decolorization etc...

Examples:

- Natural extracts/polyphenols

- Amino acids

- Antibiotics

- Vitamins

- Enzymes

- etc...

Examples:

- Molasses desugarization

- Glucose and fructose separation

- Polyols purification

- Prebiotics purification

Catalysis (Heterogeneous)

Ion exchange resins act as solid acids or bases to promote reactions sensitive to pH or as carriers for specific types of metals, without introducing any contaminant in the reaction medium, so reducing the possibility of undesirable side reactions.Examples:

- Sucrose inversion

- Bisphenol A

- MTBE/TAME

- MIBK

- MMA

- etc...

Food

During the last years food processing industries are undergoing a significant improvement of quality standards, demanding for increasing purity level for both raw materials and final products. Download the PDF Brochure

Download the PDF Brochure